As a generator of this kind of wastewater, due to its industrial chemical cleaning activities, CTP environnement offers an alternative: mobile treatment units, which allow aqueous waste to be pre-treated or concentrated on site. As a direct consequence for customer, the overall costs of transporting and disposal are significantly reduced.

Initially designed to treat effluent from cleaning operations, mobile treatment unit scope also includes special aqueous industrial waste, toxic waste, production residues and leachates.

Depending on the nature of pollutant and their concentrations, they can also be adapted to clean tanks and pools or drain processes, etc.

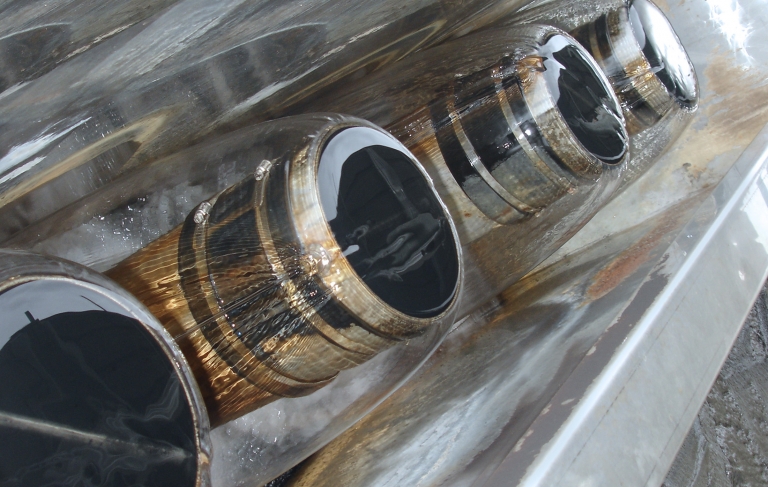

CTP equipment

CTP equipment

Induxia 13b.jpg)