All industries which may discharge large volumes of these hazardous substances, are concerned and are seeking to comply with emission limit values, keeping the associated cost acceptable. The issue is often a complex one, as when it comes to recently monitored substances (biocides and phytosanitary products, for example), treatments have not always been fully mastered.

Therefore, CTP environnement is conducting tests and dynamic on-site pilot operations in order to devise solutions and develop the appropriate technologies.

Depending on the site’s location and access to the discharge point, industrial operators may then decide whether to discharge into the natural environment or to recycle the treated stream using specific applications, to reduce the environmental footprint of their activities, while keeping raw product consumption low.

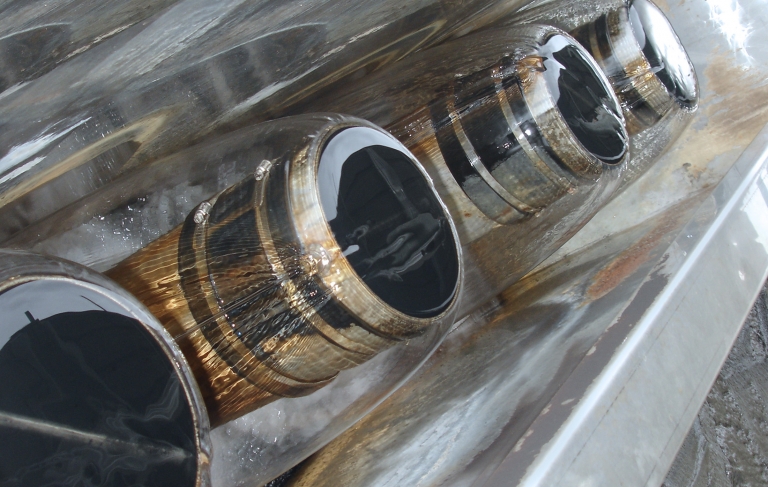

CTP equipment

CTP equipment

Induxia 13b.jpg)