Our range of services is not limited to conventional descaling of heat generation equipment, but also includes the following operations:

- Descaling, deoxidation of enamelled steel double walled reactors

- Aqueous phase decontamination

- Vapour phase decontamination

- Neutralisation of polythionic acids

- Sulphide oxidation

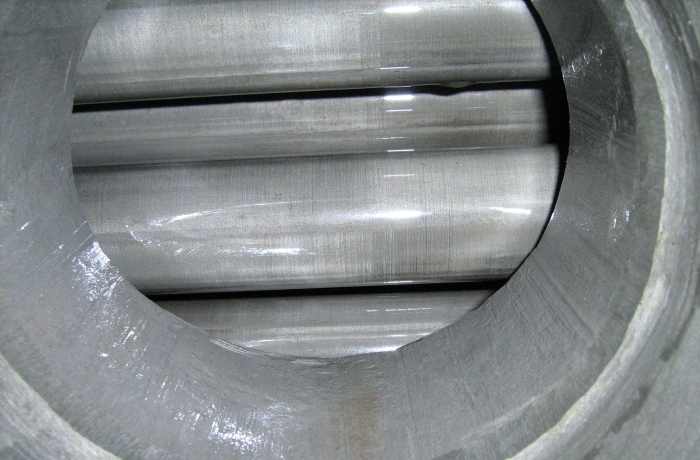

CTP equipment

CTP equipment

CTP6.jpg)